- Welcome to ST-Riders - The liST.

Recent posts

#71

ST1100 Archive of Wisdom / Re: Vacuum Fuel Valve Bypass M...

Last post by KoTAOW - March 27, 2012, 08:02:14 AMPossible alternate sources for rebuild kits as of Feb 2013:

www.partsnmore.com

and

www.carbkitscapital.com

and

www.sudco.com

and

http://www.nrp-carbs.co.uk/index.htm

www.partsnmore.com

and

www.carbkitscapital.com

and

www.sudco.com

and

http://www.nrp-carbs.co.uk/index.htm

#72

ST1100 Archive of Wisdom / Rear Wheel Inner Fender Extend...

Last post by KoTAOW - March 25, 2012, 07:31:16 PMOriginal thread here: http://www.st-riders.net/index.php?topic=1481.0

Comments by John OoSTerhuis, STOC #1058:

As some of you may have noticed, I've reported riding a few gravel and dirt roads in the last year. And most recently just this week on some wet ones, not to mention a lot of wet and sandy pavement. The ST is pretty dirty of course, but I didn't realize just quite how dirty until I pulled the fuel tank yesterday to fix a coolant leak.

Sand, dirt, pebbles... all over the top of the swingarm and the exhaust collector. YIKES! And the stuff was 1" deep on top of my AudioVox CC vacuum canister which is slung below (mostly blocking) the gap between the swingarm front cross-members:

Sorry no pictures of the actual mess. I couldn't stand it and immediately cleaned it up. Can't have an SSMST that dirty, even on the inside. :)

So... would all you folks that have farkled those cool rear wheel inner fender extensions kindly poST your pictures and how-to/materials info for me...? Please? TIA

~~~

Comments by Carroll Walker, STOC #3176:

I didn't have the tank out of the bike so I could not get photos of the other side (front side) but I think this should give you some ideas. Not sure what material I use but it is some type of plastic I had on hand. Someone told me they had used a one gallon oil container to make a fender extender. I think most any type of plastic should work as there is very little movement in the extender after installation. I could have extended the left side just a little more, maybe on the second edition!!

~~~

Comments by Chuck Henderson, STOC #086:

My KLR just happens to be on the lift waiting for tires. So here is the extender i farkled on the KLR. should give you some ideas. Just a small piece of rubber mat zipped tied to the rear fender. Silver STorm will get this farkle next time the tires are replaced.

~~~

Comments by Paul Kolbo, STOC #273:

That looks similar to the vinyl piece I attached to the inner fender on my ST1100. I bought the vinyl from Home Depot (look in the flooring section). The ST1100 allows the extender to hang down in front of the swingarm. I used small stainless steel bolts and nuts to secure the piece. I also bonded the surfaces with RTV for good measure. Sorry, I have no pictures and the bike is currently stored in the corner of the cold garage.

~~~

Comments by Don da Roza, STOC #5230:

Just a thought, but might to want to consider using rivets instead of screws as they might be more secure for that application.

Reply by Carroll Walker, STOC #3176:

I thought of that but I wanted the option of removed the extension if necessary in case I had to remove the swing-arm. The hardware I used was stainless steel and therefore will not rust plus I applied just a small amount of 'Locktite' to the threads to prevent the hardware from becoming loose. In fact I had to remove the extension one time but I can't remember the reason, must be old age!!

~~~

Comments by Jason Spradlin, STOC #5043:

Before pic shows holes drilled for mudflap indicated by yellow arrows. Have to BE CAREFUL not to drill into the battery tray when locating the left hole. Before I cleaned the swingarm it looked like the exhaust.

After photo shows mudflap installed. It should keep muck out of the swingarm pivot/engine/tranny area. Mudflap was made from a black anti-freeze jug. Simply cut out the entire front or rear area of the jug and trim to fit, then punch your two mounting holes. Mudflap could be made longer to cover exhaust but I was affraid it would melt from heat. Could maybe add thick rubber extension to the bottom for exhaust coverage.

I also made one for my FZ1 out of an actual truck mudflap from NAPA - next time the rear wheel is off the ST, I might remake one from this material for it. Pics here http://www.yamahafz1oa.com/forum/showthread.php?t=74763&highlight=mudflap

~~~

Additional comments by John OoSTerhuis, STOC #105:

I finally got around to finishing my Galfer stainless steel rear brake line installation (will post separately about that). Before reinstalling the rear wheel and fuel tank I finished up the back end with an inner fender extension:

I'd purchased a heavy plastic mud flap from AutoZone but it proved too rigid to work with and get in the proper shape and contour. Then I found a stair tread at Home Depot that you see in the picture. I think it'll work out fine. I used stainless steel screws, washers, and nyloc nuts. Here's a picture of the other, fuel tank side:

Hopefully this fender extension will keep out all the dirt that'd been collecting on/in the swingarm.

BTW, there is a commercial version available from a UK outfit, Bike-Quip:

http://www.st1300-accessories.co.uk/st1100_shock_protect.html

~~~

Thank You all for your contributions.

Rear Wheel Inner Fender Extender ( ST1100 )

Comments by John OoSTerhuis, STOC #1058:

As some of you may have noticed, I've reported riding a few gravel and dirt roads in the last year. And most recently just this week on some wet ones, not to mention a lot of wet and sandy pavement. The ST is pretty dirty of course, but I didn't realize just quite how dirty until I pulled the fuel tank yesterday to fix a coolant leak.

Sand, dirt, pebbles... all over the top of the swingarm and the exhaust collector. YIKES! And the stuff was 1" deep on top of my AudioVox CC vacuum canister which is slung below (mostly blocking) the gap between the swingarm front cross-members:

Sorry no pictures of the actual mess. I couldn't stand it and immediately cleaned it up. Can't have an SSMST that dirty, even on the inside. :)

So... would all you folks that have farkled those cool rear wheel inner fender extensions kindly poST your pictures and how-to/materials info for me...? Please? TIA

~~~

Comments by Carroll Walker, STOC #3176:

I didn't have the tank out of the bike so I could not get photos of the other side (front side) but I think this should give you some ideas. Not sure what material I use but it is some type of plastic I had on hand. Someone told me they had used a one gallon oil container to make a fender extender. I think most any type of plastic should work as there is very little movement in the extender after installation. I could have extended the left side just a little more, maybe on the second edition!!

~~~

Comments by Chuck Henderson, STOC #086:

My KLR just happens to be on the lift waiting for tires. So here is the extender i farkled on the KLR. should give you some ideas. Just a small piece of rubber mat zipped tied to the rear fender. Silver STorm will get this farkle next time the tires are replaced.

~~~

Comments by Paul Kolbo, STOC #273:

That looks similar to the vinyl piece I attached to the inner fender on my ST1100. I bought the vinyl from Home Depot (look in the flooring section). The ST1100 allows the extender to hang down in front of the swingarm. I used small stainless steel bolts and nuts to secure the piece. I also bonded the surfaces with RTV for good measure. Sorry, I have no pictures and the bike is currently stored in the corner of the cold garage.

~~~

Comments by Don da Roza, STOC #5230:

Just a thought, but might to want to consider using rivets instead of screws as they might be more secure for that application.

Reply by Carroll Walker, STOC #3176:

I thought of that but I wanted the option of removed the extension if necessary in case I had to remove the swing-arm. The hardware I used was stainless steel and therefore will not rust plus I applied just a small amount of 'Locktite' to the threads to prevent the hardware from becoming loose. In fact I had to remove the extension one time but I can't remember the reason, must be old age!!

~~~

Comments by Jason Spradlin, STOC #5043:

Before pic shows holes drilled for mudflap indicated by yellow arrows. Have to BE CAREFUL not to drill into the battery tray when locating the left hole. Before I cleaned the swingarm it looked like the exhaust.

After photo shows mudflap installed. It should keep muck out of the swingarm pivot/engine/tranny area. Mudflap was made from a black anti-freeze jug. Simply cut out the entire front or rear area of the jug and trim to fit, then punch your two mounting holes. Mudflap could be made longer to cover exhaust but I was affraid it would melt from heat. Could maybe add thick rubber extension to the bottom for exhaust coverage.

I also made one for my FZ1 out of an actual truck mudflap from NAPA - next time the rear wheel is off the ST, I might remake one from this material for it. Pics here http://www.yamahafz1oa.com/forum/showthread.php?t=74763&highlight=mudflap

~~~

Additional comments by John OoSTerhuis, STOC #105:

I finally got around to finishing my Galfer stainless steel rear brake line installation (will post separately about that). Before reinstalling the rear wheel and fuel tank I finished up the back end with an inner fender extension:

I'd purchased a heavy plastic mud flap from AutoZone but it proved too rigid to work with and get in the proper shape and contour. Then I found a stair tread at Home Depot that you see in the picture. I think it'll work out fine. I used stainless steel screws, washers, and nyloc nuts. Here's a picture of the other, fuel tank side:

Hopefully this fender extension will keep out all the dirt that'd been collecting on/in the swingarm.

BTW, there is a commercial version available from a UK outfit, Bike-Quip:

http://www.st1300-accessories.co.uk/st1100_shock_protect.html

~~~

Thank You all for your contributions.

#73

ST1100 Archive of Wisdom / Re: Ron Major's 3.6 Aux Fuel C...

Last post by KoTAOW - March 14, 2012, 08:12:08 PMThese Ron Major 3.6 gallon fuel cells are available at: Sampson-Sporttouring

Approximately $600 ( March 2012 prices plus additional hardware kit)

Approximately $600 ( March 2012 prices plus additional hardware kit)

#74

ST1100 Archive of Wisdom / Swing Arm Maintenance ( ST1100...

Last post by KoTAOW - March 08, 2012, 08:03:21 AMSubmitted by Robert Martin, STOC #6653

Original article can be found here: http://www.st-1100.com/swing-arm-maintenance.html

~~~

Background

Well the Pan needed its annual MOT - it passed without any problems, but the tester pointed out that the rear swing arm was rusting. "These bikes go for many thousands of miles without a problem, but all of them experience rust in this area", he said. I dutifully promised to look into it.

Now, not being someone who does things by halves, I decided to remove the entire swing arm so that it could be properly inspected, repaired and painted.

Halfway through the operation I found myself asking "Why???"

"Why did I start this?"

"Why not take it to a Honda Dealer?" (Because I'm a cheapskate and begrudge the Honda mechanics charging me an arm and a leg).

So, you're thinking of doing this yourself?

Read on. It's not for the faint-hearted.

Firstly, you'll need the following:

Er, wait a minute. Did you say "Fargling iron?" What's a fargling iron? Read on, you'll see.

So, ready to start?

Remove the panniers, seat and side panels. (I'm not going to detail the procedure for this - if you haven't worked out how to remove the panniers, seat and side panels yet, stop reading now and take the bike to a Honda dealer. Seriously.)

Remove the triangular infill panels near the footrests:

Remove the rear mudguard (this makes access so much easier):

Remove the rear wheel.

This gave a closer view of what the MOT tester had spotted:

Drain the final drive oil.

Now spray all the bolts that you're going to remove (shock absorber lower mounting bolt, drive assembly bolts, brake line clip bolts) with a penetrating oil - I used WD-40.

Have lunch and a lie-down. You're going to need your strength.

Tie up the brake caliper so that the brake hose is not stretched.

Remove the brake line holding clip (the rear one).

Remove the brake line holding clip (the middle one).

Remove the brake line holding clip (the front one - NOW you need your long-handled fargling iron in order to undo the brake line holding clip at the front of the swing arm. It may be easier if you turn the entire ST1100 upside down, but not much. If you know anyone who is triple-jointed with two extra elbows now is the time to call in that favour.)

Failing this, use an 8mm spanner and patience. A lot of patience. Nearly an hour's worth of patience. To remove one bolt. There's just enough room to turn the bolt 1⁄16th of a revolution for every application of the spanner.

So, bolt removed? Go and have a cup of tea. You deserve it.

Now remove the lower shock absorber bolt. At around this time you start to wonder why you didn't just take the bike to the Honda dealership in the first place - yes, the bolt IS seized.

Honda in their wisdom decided to make this bolt out of Gruyere cheese - the head rounds off if you just sneeze on it. I found a Stilson wrench a most useful item here.

Okay, so the bolt's out. Not in very good condition mind you - but it's out.

Order new bolt.

So, now we're ready to remove the drive housing (you DID remember to drain the oil, didn't you?)

Loosen the 4 nuts holding the drive housing. Well, that's the theory. In practice you will find the nuts are seized to the studs, so the studs themselves unscrew. Never mind. Prepare your angle grinder with a cutting disc for the 4th nut, because not only is this one seized to the stud, the stud itself is seized in the drive housing. Which shouldn't be a problem. Normally.

Carefully cut through 1/4 of the nut. Then with a hammer and chisel you should be able to tap it around until it comes off. Now I'll bet you any money you like that THIS damaged stud is the only one which remains properly in its housing.

The other three nuts come off with studs attached.

Order new studs and nuts.

Now pull the drive shaft as far towards the rear of the bike as you can (as long as you have fingers like Edward Scissorhands and a grip like the Incredible Hulk). Those with stubby fingers will struggle here. This is to disengage the universal joint from the transmission output shaft.

Now in order to remove the swing-arm pivot bolts...

... we need Honda special tool number 07908-4690003. Special tool? Huh! Herewith the cunning plan. I have some "Polymorph" - this is a plastic which is hard at normal room temperature, but if heated to around 70 degrees C becomes soft and malleable. I believe it's the same stuff which is used in hot glue guns. I heated some in hot water, and then pressed it in around the pivot bolt.

Once it had set (which took a couple of minutes), I carefully removed it. This gave me an impression of what the special tool had to look like.

The outside diameter needs to be 38mm. Casting around the workshop, I found an old spade which seemed to fit the bill. I cut off the blade bit, welded a large bolt into one end, then using a hacksaw followed by an angle grinder, trimmed the other end so that there were 4 "cut-outs" of the right size.

This enables the removal of the pivot bolt locknut.

To remove the pivot bolt itself, I bought a drain plug key off Ebay for about £1 (Fits Ford, BMW, Lancia, Mercedes and Volkswagen)!

One side takes a 14mm spanner/socket, and the other side a 17mm spanner/socket - just the right size to fit the socket in the pivot bolt.

Propping the swing-arm in place with a chunk of wood, I removed both pivot bolts.

Removing the swing-arm from the frame was a bit of a struggle as there is a lip near the right-hand pivot bolt, but it finally came free. The driveshaft was then removed from the front of the swing-arm.

The driveshaft and universal joint were in very good condition. The swing-arm, however, was not. Here's a closer look at the reason we're doing this:

Before tackling the swing-arm, I decided to remove the stuck stud from the drive housing. This was done by the simple expedient of welding a nut onto the end of the stud. The heat from the welding (and the added grip from the nut of course!) enabled easy removal of the stud.

Finally - repairing the swing-arm itself.

The first thing to do is to remove any badly-rusted areas. I did this with a small cutoff wheel on my Dremel grinder.

Whilst I was at it, I drilled a drain hole so that any water that gets into the swingarm can run out - it's visible on the right of the photo above.

Using some scrap steel, I cut out an infill piece and held it in place with a magnet prior to welding (the magnet comes out of an old computer hard drive - it's neodymium and very powerful!)

For the curved section, I made a template from cardboard first:

I then cut a section from scrap steel and welded it in place:

Having smoothed out the welds, I then used a wire brush on the angle grinder to remove all paint and rust from the entire swing-arm.

Once this was done, I wiped down the surface using thinners, and then applied a coat of Unidox zinc primer - this stuff is 90% zinc!

Finally I applied two coats of Hammerite black paint.

Replacing everything

Now, to quote Mr Haynes, "Installation is the reverse of removal".

No kidding.

I coated the driveshaft splines with molybdenum disulphide grease (available in small tubes from your Honda dealer - it's worth buying as it lasts for absolute ages). The driveshaft was then inserted back into the swing-arm, and the rubber gaiter fitted (more fun with this follows...)

Don't forget to put a dab of grease in each swing-arm bearing before reinstallation!

The swing-arm was then reinstalled and the pivot bolts inserted.

At this point you have to make sure that the front drive shaft seal is properly over the lips of the transmission casing. Your friend with two extra elbows can once again lend assistance here - it's a real pain. Unless you remove the entire engine from the frame, which somewhat defeats the objective anyway.

The pivot bolts are then tightened to the correct torque - 105Nm for the right and 18Nm for the left. The left pivot bolt locknut is then tightened to 105Nm. Make sure the swingarm moves freely up and down.

The driveshaft housing was then re-attached, and the new shock absorber lower bolt fitted. I used copper grease on all bolts when refitting them; this should prevent future seizures.

I then reinstalled the brake line holding clips, once again having tremendous fun with the front one.

I decided to install a mudguard extension at this stage. Using a piece of flexible plastic (no idea where it came from!) I cut it to fit inside the mudguard, and fitted it using some plastic upholstery clips.

Once fitted, I found it needed to be trimmed slightly to avoid fouling the rear wheel. I think an old rubber car mat would be better - that's a future project for the next time I take the rear wheel off!

Update: a rubber car mat does indeed fit better; it's more flexible:

~~~

Comments by KotAOW: Be sure to follow the correct Final Drive Alignment and Torque Sequence which can be found here:

http://www.st-riders.net/index.php?topic=3748.0

~~~

Finally the rear wheel was refitted, followed by the mudguard, side panels and seat.

So, in conclusion, is it feasible to do this? Yes. Although what you may consider doing is purchasing a second-hand swing-arm from somewhere like Ebay, and renovating that. Then take the bike with the newly-renovated swing-arm to a trusted mechanic and have him swop it over.

(Of course you can then renovate your old swing-arm and sell that on Ebay, recovering some of your costs!)

~~~

Thanks for your contribution Robert Martin, STOC #6653

Original article can be found here: http://www.st-1100.com/swing-arm-maintenance.html

~~~

Swing Arm Maintenance ( ST1100 )

Background

Well the Pan needed its annual MOT - it passed without any problems, but the tester pointed out that the rear swing arm was rusting. "These bikes go for many thousands of miles without a problem, but all of them experience rust in this area", he said. I dutifully promised to look into it.

Now, not being someone who does things by halves, I decided to remove the entire swing arm so that it could be properly inspected, repaired and painted.

Halfway through the operation I found myself asking "Why???"

"Why did I start this?"

"Why not take it to a Honda Dealer?" (Because I'm a cheapskate and begrudge the Honda mechanics charging me an arm and a leg).

So, you're thinking of doing this yourself?

Read on. It's not for the faint-hearted.

Firstly, you'll need the following:

- A selection of screwdrivers, sockets and spanners

- Honda special tool 07908-4690003 (I'll come to that later - there is a CUNNING PLAN for this item)

- A long-handled fargling iron

- Hammer

- Cold chisel, preferably a sharp one

- Angle grinder with cutoff disc

- Large tin of WD-40

- Goggles

- Earmuffs

- Overalls

- Paint

- Flask of tea

- Several days off work

Er, wait a minute. Did you say "Fargling iron?" What's a fargling iron? Read on, you'll see.

So, ready to start?

Remove the panniers, seat and side panels. (I'm not going to detail the procedure for this - if you haven't worked out how to remove the panniers, seat and side panels yet, stop reading now and take the bike to a Honda dealer. Seriously.)

Remove the triangular infill panels near the footrests:

Remove the rear mudguard (this makes access so much easier):

Remove the rear wheel.

This gave a closer view of what the MOT tester had spotted:

Drain the final drive oil.

Now spray all the bolts that you're going to remove (shock absorber lower mounting bolt, drive assembly bolts, brake line clip bolts) with a penetrating oil - I used WD-40.

Have lunch and a lie-down. You're going to need your strength.

Tie up the brake caliper so that the brake hose is not stretched.

Remove the brake line holding clip (the rear one).

Remove the brake line holding clip (the middle one).

Remove the brake line holding clip (the front one - NOW you need your long-handled fargling iron in order to undo the brake line holding clip at the front of the swing arm. It may be easier if you turn the entire ST1100 upside down, but not much. If you know anyone who is triple-jointed with two extra elbows now is the time to call in that favour.)

Failing this, use an 8mm spanner and patience. A lot of patience. Nearly an hour's worth of patience. To remove one bolt. There's just enough room to turn the bolt 1⁄16th of a revolution for every application of the spanner.

So, bolt removed? Go and have a cup of tea. You deserve it.

Now remove the lower shock absorber bolt. At around this time you start to wonder why you didn't just take the bike to the Honda dealership in the first place - yes, the bolt IS seized.

Honda in their wisdom decided to make this bolt out of Gruyere cheese - the head rounds off if you just sneeze on it. I found a Stilson wrench a most useful item here.

Okay, so the bolt's out. Not in very good condition mind you - but it's out.

Order new bolt.

So, now we're ready to remove the drive housing (you DID remember to drain the oil, didn't you?)

Loosen the 4 nuts holding the drive housing. Well, that's the theory. In practice you will find the nuts are seized to the studs, so the studs themselves unscrew. Never mind. Prepare your angle grinder with a cutting disc for the 4th nut, because not only is this one seized to the stud, the stud itself is seized in the drive housing. Which shouldn't be a problem. Normally.

Carefully cut through 1/4 of the nut. Then with a hammer and chisel you should be able to tap it around until it comes off. Now I'll bet you any money you like that THIS damaged stud is the only one which remains properly in its housing.

The other three nuts come off with studs attached.

Order new studs and nuts.

Now pull the drive shaft as far towards the rear of the bike as you can (as long as you have fingers like Edward Scissorhands and a grip like the Incredible Hulk). Those with stubby fingers will struggle here. This is to disengage the universal joint from the transmission output shaft.

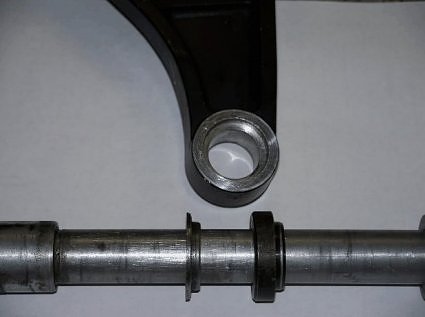

Now in order to remove the swing-arm pivot bolts...

... we need Honda special tool number 07908-4690003. Special tool? Huh! Herewith the cunning plan. I have some "Polymorph" - this is a plastic which is hard at normal room temperature, but if heated to around 70 degrees C becomes soft and malleable. I believe it's the same stuff which is used in hot glue guns. I heated some in hot water, and then pressed it in around the pivot bolt.

Once it had set (which took a couple of minutes), I carefully removed it. This gave me an impression of what the special tool had to look like.

The outside diameter needs to be 38mm. Casting around the workshop, I found an old spade which seemed to fit the bill. I cut off the blade bit, welded a large bolt into one end, then using a hacksaw followed by an angle grinder, trimmed the other end so that there were 4 "cut-outs" of the right size.

This enables the removal of the pivot bolt locknut.

To remove the pivot bolt itself, I bought a drain plug key off Ebay for about £1 (Fits Ford, BMW, Lancia, Mercedes and Volkswagen)!

One side takes a 14mm spanner/socket, and the other side a 17mm spanner/socket - just the right size to fit the socket in the pivot bolt.

Propping the swing-arm in place with a chunk of wood, I removed both pivot bolts.

Removing the swing-arm from the frame was a bit of a struggle as there is a lip near the right-hand pivot bolt, but it finally came free. The driveshaft was then removed from the front of the swing-arm.

The driveshaft and universal joint were in very good condition. The swing-arm, however, was not. Here's a closer look at the reason we're doing this:

Before tackling the swing-arm, I decided to remove the stuck stud from the drive housing. This was done by the simple expedient of welding a nut onto the end of the stud. The heat from the welding (and the added grip from the nut of course!) enabled easy removal of the stud.

Finally - repairing the swing-arm itself.

The first thing to do is to remove any badly-rusted areas. I did this with a small cutoff wheel on my Dremel grinder.

Whilst I was at it, I drilled a drain hole so that any water that gets into the swingarm can run out - it's visible on the right of the photo above.

Using some scrap steel, I cut out an infill piece and held it in place with a magnet prior to welding (the magnet comes out of an old computer hard drive - it's neodymium and very powerful!)

For the curved section, I made a template from cardboard first:

I then cut a section from scrap steel and welded it in place:

Having smoothed out the welds, I then used a wire brush on the angle grinder to remove all paint and rust from the entire swing-arm.

Once this was done, I wiped down the surface using thinners, and then applied a coat of Unidox zinc primer - this stuff is 90% zinc!

Finally I applied two coats of Hammerite black paint.

Replacing everything

Now, to quote Mr Haynes, "Installation is the reverse of removal".

No kidding.

I coated the driveshaft splines with molybdenum disulphide grease (available in small tubes from your Honda dealer - it's worth buying as it lasts for absolute ages). The driveshaft was then inserted back into the swing-arm, and the rubber gaiter fitted (more fun with this follows...)

Don't forget to put a dab of grease in each swing-arm bearing before reinstallation!

The swing-arm was then reinstalled and the pivot bolts inserted.

At this point you have to make sure that the front drive shaft seal is properly over the lips of the transmission casing. Your friend with two extra elbows can once again lend assistance here - it's a real pain. Unless you remove the entire engine from the frame, which somewhat defeats the objective anyway.

The pivot bolts are then tightened to the correct torque - 105Nm for the right and 18Nm for the left. The left pivot bolt locknut is then tightened to 105Nm. Make sure the swingarm moves freely up and down.

The driveshaft housing was then re-attached, and the new shock absorber lower bolt fitted. I used copper grease on all bolts when refitting them; this should prevent future seizures.

I then reinstalled the brake line holding clips, once again having tremendous fun with the front one.

I decided to install a mudguard extension at this stage. Using a piece of flexible plastic (no idea where it came from!) I cut it to fit inside the mudguard, and fitted it using some plastic upholstery clips.

Once fitted, I found it needed to be trimmed slightly to avoid fouling the rear wheel. I think an old rubber car mat would be better - that's a future project for the next time I take the rear wheel off!

Update: a rubber car mat does indeed fit better; it's more flexible:

~~~

Comments by KotAOW: Be sure to follow the correct Final Drive Alignment and Torque Sequence which can be found here:

http://www.st-riders.net/index.php?topic=3748.0

~~~

Finally the rear wheel was refitted, followed by the mudguard, side panels and seat.

So, in conclusion, is it feasible to do this? Yes. Although what you may consider doing is purchasing a second-hand swing-arm from somewhere like Ebay, and renovating that. Then take the bike with the newly-renovated swing-arm to a trusted mechanic and have him swop it over.

(Of course you can then renovate your old swing-arm and sell that on Ebay, recovering some of your costs!)

~~~

Thanks for your contribution Robert Martin, STOC #6653

#75

ST1300 Archive of Wisdom / Brands of Car Tires and PSI ( ...

Last post by KoTAOW - March 05, 2012, 03:15:10 PMFollowing comments by KotAOW:

Disclaimer:

The information contained in this article is for general information only. Whilst the author(s) endeavors to ensure the accuracy of this general information, no statement, representation, warranty or guarantee, express or implied, is given as to its accuracy or appropriateness for use in any particular circumstances.

The author(s) are NOT responsible for any loss or damage whatsoever arising out of or in connection with any information on this specific subject. Users are responsible for making their own assessment of all information contained in this article and are advised to verify such information.

~~~

Purpose:

This article is NOT to be considered a "how-to or step-by-step" procedure for converting your ST1300 to use a Car Tire on the rear.

Also, this article shouldn't be construed as a place to debate the use of a Car Tire on a motorcycle. That subject has been thoroughly scrutinized enough elsewhere by many believers and non-believers.

Each rider must determine the advantages and dis-advantages before continuing down this path to the "Darkside."

~~~

Brands of Car Tires and the PSI that have been documented: https://docs.google.com/spreadsheet/ccc?key=0AlXtTscE0XbLdEsyN283MEJieWJIS3ctZTgwVWZjR0E#gid=0

NOTE: This information gathered March, 2012.

~~~

Sources ( 3/2012 ):

Falken Ziex ZE-512 XL 93V B - $99.00

Hankook Ventus Sport K104 - $115.00

Hankook Ventus V12 Evo K110 - $115.00

Goodyear Assurance Triple Tred - $179.00

Michelin Pilot Sport A/S Plus - $186.00

Disclaimer:

The information contained in this article is for general information only. Whilst the author(s) endeavors to ensure the accuracy of this general information, no statement, representation, warranty or guarantee, express or implied, is given as to its accuracy or appropriateness for use in any particular circumstances.

The author(s) are NOT responsible for any loss or damage whatsoever arising out of or in connection with any information on this specific subject. Users are responsible for making their own assessment of all information contained in this article and are advised to verify such information.

~~~

Purpose:

This article is NOT to be considered a "how-to or step-by-step" procedure for converting your ST1300 to use a Car Tire on the rear.

Also, this article shouldn't be construed as a place to debate the use of a Car Tire on a motorcycle. That subject has been thoroughly scrutinized enough elsewhere by many believers and non-believers.

Each rider must determine the advantages and dis-advantages before continuing down this path to the "Darkside."

~~~

Brands of Car Tires and PSI ( ST1300 )

Brands of Car Tires and the PSI that have been documented: https://docs.google.com/spreadsheet/ccc?key=0AlXtTscE0XbLdEsyN283MEJieWJIS3ctZTgwVWZjR0E#gid=0

NOTE: This information gathered March, 2012.

| Source | Location | Brand \ Size | PSI | Mileage | Comments |

| iRide | Rear | Hankook Ventus Sport K104 205X50X17 | 45 PSI | 10,000 | Little tight getting on but no rubbing. |

| Front | Dunlop Elite # 3 130X70X18 | 42 PSI | |||

| redst05 | Rear | Hankook Ventus Sport K104 205X50X17 | 42 PSI | 3,000 | Most of my riding is one up and 60-70% slab type riding. |

| Front | Metzler, Z6 120X60X18 | 42 PSI | |||

| W0QNX | Rear | Hankook Ventus Sport K104 205X50X17 | 30 PSI | 22,000 | |

| Front | |||||

| poptheshark | Rear | Falken ZIEX ZE-512 XL 93V B 205X50RX17 | 40 PSI | ?,??? | So far it handles well. |

| Front | |||||

| JasonFJ | Rear | Falken ZIEX ZE-512 XL 93V B 205X50RX17 | 40 PSI | ?,??? | |

| Front | Michelin PR2 | 42 PSI | |||

| 970Mike | Rear | Goodyear Assurance Triple Tred 205X50RX17 | 32-35 PSI | 5,000 | |

| Front | |||||

| DaveST | Rear | Hankook Ventus K110 205/50/ZR17 | 40 PSI | 1,200 | |

| Front | Michelin PR2 | 42 PSI | |||

| HR Cole | Rear | Hankook Ventus K110 205/50/ZR17 | 5,000 | ||

| Front | |||||

| LeeWonnacott | Rear | Hankook Ventus K110 205/50/ZR17 | 6,000 | ||

| Front | |||||

| JoeP_Dallas | Rear | Hankook Ventus K110 205/50/ZR17 | 3,000 | ||

| Front | |||||

| nhdiesel | Rear | Hankook Ventus K110 205/50/ZR17 | 17,000 | ||

| Front | |||||

| Zooker13 | Rear | Hankook Ventus K110 205/50/ZR17 | 30 PSI | 23,000 | |

| Front | |||||

| 970Mike | Rear | Hankook Ventus K110 205/50/ZR17 | 40 PSI | 19,000 | |

| Front | |||||

| JCB | Rear | Hankook Ventus K110 205/50/ZR17 | 40 PSI | 3,500 | Two up, with trailer |

| Front | |||||

| Dinkie Diesel | Rear | Michelin Pilot Sport A/S Plus 205X50RX17 | ?,??? | ||

| Front |

~~~

Sources ( 3/2012 ):

Falken Ziex ZE-512 XL 93V B - $99.00

Hankook Ventus Sport K104 - $115.00

Hankook Ventus V12 Evo K110 - $115.00

Goodyear Assurance Triple Tred - $179.00

Michelin Pilot Sport A/S Plus - $186.00

#76

ST1100 Archive of Wisdom / Re: Converting Rear Wheel and ...

Last post by KoTAOW - March 05, 2012, 11:22:28 AMPictures and text provided by Daniel Foell, aka The Dan, STOC #7982:

Tire mounted.

Test fit. Needs to move left 7/32.

The start.

The shim for the flange to keep the splines in the correct place. yup molly on it.

Spacer slips on the factory spacer.

The spacer in place. moves the wheel 7/32 over.

Used the stock spacer and the spacer that came with the Goldwing wheel + .35 shim.

Will machine the correct spacer now that I know what it needs.

Caliper mount.

See like this.

It slides this far over.

Drive side spacer.

Took out the thick spacer drove in the thin.

Took 7/32 off the caliper mount. made a spacer for the drive side.

Use the factory insert.

Plenty of room after the move over.

Sets good now.

The Darkside Baby.

Hitch = no problem.

~~~

Thank You for your contribution Daniel Foell, aka The Dan, STOC #7982

Converting Rear Wheel and Mounting a Car Tire - continued ( ST1100 )

Tire mounted.

Test fit. Needs to move left 7/32.

The start.

The shim for the flange to keep the splines in the correct place. yup molly on it.

Spacer slips on the factory spacer.

The spacer in place. moves the wheel 7/32 over.

Used the stock spacer and the spacer that came with the Goldwing wheel + .35 shim.

Will machine the correct spacer now that I know what it needs.

Caliper mount.

See like this.

It slides this far over.

Drive side spacer.

Took out the thick spacer drove in the thin.

Took 7/32 off the caliper mount. made a spacer for the drive side.

Use the factory insert.

Plenty of room after the move over.

Sets good now.

The Darkside Baby.

Hitch = no problem.

~~~

Thank You for your contribution Daniel Foell, aka The Dan, STOC #7982

#77

ST1100 Archive of Wisdom / Re: Converting Rear Wheel and ...

Last post by KoTAOW - March 05, 2012, 11:21:38 AMAdditional information provided by Mark Kunath, aka Bigmak96, STOC #7910

I am sure there are many riders who feel this is not the thing to do. I would like to thank those riders for allowing us to go to the "Darkside" with what has been a minimum of public ridicule. I will be the first to say, it should not work as well as it does,and it sounds like a very stupid thing to do when you think about what a car tire looks like compared to a standard motor cycle tire. All I can say is it does work. If you have doubts about it, by all means, don't do it. If on the other hand you are curious and would like to see what it feels like, I am sure most guys running a car tire would be happy to let you take a spin on their bike. It does feel different, but so does every new tire I have ever put on. It was surprising to me how quickly the difference felt like the norm. Getting huge mileage makes that difference worth it to me.

So, with that out of the way, here is what it takes to run a car tire on the ST1100 without ABS.

~~~

You need to use a wheel from the later offering of the GL1500. Those bikes used the same 5 pin spider we use in our final drive. Use your bikes original spider if the wheel you find has the spider with it. Don't introduce a different wear pattern with a different spider!

The GL1500 wheel is not as wide as the stock ST1100 wheel either in rim width or measured over the bearing faces. Given that fact, the wheel needs to move to the left to center the wheel with the bike.

To do this, there are some spacers needed, and some alterations to the brake hanger that need to be done.

These sizes are not set in stone, but are what Dan Foell, aka The Dan, STOC #7982 determined to be correct to get the proper shift to the left. I say not set in stone because there is some leeway allowed. It would be possible to make the total width too wide to fit between the swing arm, and that would not work, but being less wide would be fine. I would guess you would be hard pressed to tell if the axle were pulled another 0.050" to the right when you tightened the axle nut. And since the shoulder of the axle pulls everything together when the nut is tightened, I feel it would be a moot point.

These are ALL the parts needed or need modified to convert the ST1100, without ABS to accept a Car Tire.

TOP is the modified caliper hanger. Below on the LEFT, Item #1 is the caliper hanger shim, second from the left, Item #2 is the left side axle spacer, third from the left, Item #3 is the right side, spacer tube extension and finally, on the right, Item #4 is the replacement thrust washer.

(1) The thin nylon washer that goes into the spider is replaced with a 0.25" wide replacement. 0.25" X 2.46" O.D. X 1.75" I.D., Item #4.

(2) The spacer tube that extends out of the final drive is extended by a piece that slips over the O.D. of the spacer tube. This piece has a 0.22" shoulder that butts up to the original spacer tube. Item #3.

I made mine 1.25" O.D. with an 0.805" through hole. The 1.030" I.D. that slips onto the spacer tube stops short of going through, creating a shoulder of 0.220'. This shoulder is what makes the wheel move to the left to accommodate the GL1500 wheel.

~~~

OK, the wheel is now shifted to the left. The next steps are needed to accommodate the total width of the wheel and get the brake hanger in the right plane to get the pads where they need to be.

(3) The original spacer that fits into the dust seal of the left bearing is not used. It is replaced with one of the same I.D. and O.D. but

it is 1.540" long. The O.D. is 1.182". This fits snugly into the dust seal of the bearing. The I.D. is 0.79" or a close slip fit to the axle's O.D. thus keeping it concentric with the bearing and seal. Item #2.

Those are the three spacers needed.

~~~

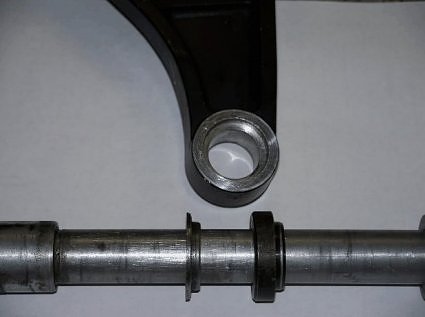

This picture shows the two axle spacers together. The one on the right is the one that slips on the end of the stock spacer tube in the final drive. The other just to the right of the hanger is the spacer that goes between the wheel and the hanger.

~~~

Now for the brake hanger alterations.

Given that the brake disk is not in the same plane that it is with the stock wheel, the hanger needs to make a shift to the left as well. This is done one of two ways. Either you can heat up the hanger to allow you to get the steel axle bushing out and then replace it with one with a thinner flange, or you can have your local machine shop mill off some of the original bushing. If you choose to mill the original and leave it in, another spacer will need to be made so in the event you want to leave this crazy Darkside, you will be able to put your hanger back in it's original position. If you leave it in, you need to have 0.230" milled from the original and make a spacer 0.230" thick to put in if you want to go back to stock. This leaves 0.062" of the original flange, which lets the hanger move to the left by 0.230". Item #1.

If you take the original steel bushing out, you need to have a replacement made that has a 0.062" wide flange. It is more work doing it this way as you have to turn just a little off the small diameter of the original, so it can slip back into the hanger if you go back. The new one with the 0.062" flange needs to slip into the hanger where the old bushing was. I did mine this way but will opt for the additional spacer method in the future. It was way more work than it was worth.

The shift to the left makes it necessary to mill some material from the lower rib on the brake hanger so it can rotate into position. I wish I had exact info on that but I don't at this time. If I do another conversion, I will try to document it better. The picture above shows where to do it. It's not real important how much, other than it needs to be enough. ;>) If you can do, or have done, the other work first, you can put your axle through the hanger and rotate it down to see where and how much to take stock off.

One final step. the boss that the forward pin goes through to keep the caliper hanger in position, needs to be milled. I took 1/4" off it to allow the shift to the left.

That is it. You can now install your GL1500 wheel.

~~~

If you have an ST1100, with ABS, there is another rather major hurdle to get over. The pulse ring needs to be mounted on columns to get it in the right plane. I will pass on explaining that now, but I will if there is an ABS owner that needs to know.

The pictures do show what needs to happen.

~~~

I want to stress that I am NOT trying to drum up work here. It really is kind of a PITA to make the parts and do the milling so it is not something I am trying to stay busy with. I would much prefer to talk to your local machine shop to answer any questions so you can have it done locally. For what it's worth, the ST1300 is a much easier platform to work with. They can just mount a tire.

~~~

Thank You for your contribution Mark Kunath, aka Bigmak96, STOC #7910

Converting Rear Wheel and Mounting a Car Tire - continued ( ST1100 )

I am sure there are many riders who feel this is not the thing to do. I would like to thank those riders for allowing us to go to the "Darkside" with what has been a minimum of public ridicule. I will be the first to say, it should not work as well as it does,and it sounds like a very stupid thing to do when you think about what a car tire looks like compared to a standard motor cycle tire. All I can say is it does work. If you have doubts about it, by all means, don't do it. If on the other hand you are curious and would like to see what it feels like, I am sure most guys running a car tire would be happy to let you take a spin on their bike. It does feel different, but so does every new tire I have ever put on. It was surprising to me how quickly the difference felt like the norm. Getting huge mileage makes that difference worth it to me.

So, with that out of the way, here is what it takes to run a car tire on the ST1100 without ABS.

~~~

You need to use a wheel from the later offering of the GL1500. Those bikes used the same 5 pin spider we use in our final drive. Use your bikes original spider if the wheel you find has the spider with it. Don't introduce a different wear pattern with a different spider!

The GL1500 wheel is not as wide as the stock ST1100 wheel either in rim width or measured over the bearing faces. Given that fact, the wheel needs to move to the left to center the wheel with the bike.

To do this, there are some spacers needed, and some alterations to the brake hanger that need to be done.

These sizes are not set in stone, but are what Dan Foell, aka The Dan, STOC #7982 determined to be correct to get the proper shift to the left. I say not set in stone because there is some leeway allowed. It would be possible to make the total width too wide to fit between the swing arm, and that would not work, but being less wide would be fine. I would guess you would be hard pressed to tell if the axle were pulled another 0.050" to the right when you tightened the axle nut. And since the shoulder of the axle pulls everything together when the nut is tightened, I feel it would be a moot point.

These are ALL the parts needed or need modified to convert the ST1100, without ABS to accept a Car Tire.

TOP is the modified caliper hanger. Below on the LEFT, Item #1 is the caliper hanger shim, second from the left, Item #2 is the left side axle spacer, third from the left, Item #3 is the right side, spacer tube extension and finally, on the right, Item #4 is the replacement thrust washer.

(1) The thin nylon washer that goes into the spider is replaced with a 0.25" wide replacement. 0.25" X 2.46" O.D. X 1.75" I.D., Item #4.

(2) The spacer tube that extends out of the final drive is extended by a piece that slips over the O.D. of the spacer tube. This piece has a 0.22" shoulder that butts up to the original spacer tube. Item #3.

I made mine 1.25" O.D. with an 0.805" through hole. The 1.030" I.D. that slips onto the spacer tube stops short of going through, creating a shoulder of 0.220'. This shoulder is what makes the wheel move to the left to accommodate the GL1500 wheel.

~~~

OK, the wheel is now shifted to the left. The next steps are needed to accommodate the total width of the wheel and get the brake hanger in the right plane to get the pads where they need to be.

(3) The original spacer that fits into the dust seal of the left bearing is not used. It is replaced with one of the same I.D. and O.D. but

it is 1.540" long. The O.D. is 1.182". This fits snugly into the dust seal of the bearing. The I.D. is 0.79" or a close slip fit to the axle's O.D. thus keeping it concentric with the bearing and seal. Item #2.

Those are the three spacers needed.

~~~

This picture shows the two axle spacers together. The one on the right is the one that slips on the end of the stock spacer tube in the final drive. The other just to the right of the hanger is the spacer that goes between the wheel and the hanger.

~~~

Now for the brake hanger alterations.

Given that the brake disk is not in the same plane that it is with the stock wheel, the hanger needs to make a shift to the left as well. This is done one of two ways. Either you can heat up the hanger to allow you to get the steel axle bushing out and then replace it with one with a thinner flange, or you can have your local machine shop mill off some of the original bushing. If you choose to mill the original and leave it in, another spacer will need to be made so in the event you want to leave this crazy Darkside, you will be able to put your hanger back in it's original position. If you leave it in, you need to have 0.230" milled from the original and make a spacer 0.230" thick to put in if you want to go back to stock. This leaves 0.062" of the original flange, which lets the hanger move to the left by 0.230". Item #1.

If you take the original steel bushing out, you need to have a replacement made that has a 0.062" wide flange. It is more work doing it this way as you have to turn just a little off the small diameter of the original, so it can slip back into the hanger if you go back. The new one with the 0.062" flange needs to slip into the hanger where the old bushing was. I did mine this way but will opt for the additional spacer method in the future. It was way more work than it was worth.

The shift to the left makes it necessary to mill some material from the lower rib on the brake hanger so it can rotate into position. I wish I had exact info on that but I don't at this time. If I do another conversion, I will try to document it better. The picture above shows where to do it. It's not real important how much, other than it needs to be enough. ;>) If you can do, or have done, the other work first, you can put your axle through the hanger and rotate it down to see where and how much to take stock off.

One final step. the boss that the forward pin goes through to keep the caliper hanger in position, needs to be milled. I took 1/4" off it to allow the shift to the left.

That is it. You can now install your GL1500 wheel.

~~~

If you have an ST1100, with ABS, there is another rather major hurdle to get over. The pulse ring needs to be mounted on columns to get it in the right plane. I will pass on explaining that now, but I will if there is an ABS owner that needs to know.

The pictures do show what needs to happen.

~~~

I want to stress that I am NOT trying to drum up work here. It really is kind of a PITA to make the parts and do the milling so it is not something I am trying to stay busy with. I would much prefer to talk to your local machine shop to answer any questions so you can have it done locally. For what it's worth, the ST1300 is a much easier platform to work with. They can just mount a tire.

~~~

Thank You for your contribution Mark Kunath, aka Bigmak96, STOC #7910

#78

ST1100 Archive of Wisdom / Converting Rear Wheel and Moun...

Last post by KoTAOW - March 05, 2012, 11:19:02 AMInformation provided by Mark Kunath, aka Bigmak96, STOC #7910

~~~

Following comments by KotAOW:

Disclaimer:

The information contained in this article is for general information only. Whilst the author(s) endeavors to ensure the accuracy of this general information, no statement, representation, warranty or guarantee, express or implied, is given as to its accuracy or appropriateness for use in any particular circumstances.

The author(s) are NOT responsible for any loss or damage whatsoever arising out of or in connection with any information on this specific subject. Users are responsible for making their own assessment of all information contained in this article and are advised to verify such information.

~~~

Purpose:

This article is a collection of many threads posted on different motorcycle forums. It is NOT to be considered a "how-to or step-by-step" procedure for converting your ST1100 w\o ABS to use a Car Tire on the rear.

Also, this article shouldn't be construed as a place to debate the use of a Car Tire on a motorcycle. That subject has been thoroughly scrutinized enough elsewhere by many believers and non-believers.

Each rider must determine the advantages and dis-advantages before continuing down this path to the "Darkside."

~~~

Comments by Mark Kunath:

In order to use a Car Tire or CT on a ST1100 you need to convert to the Honda GL1500 wheel as there is no CT to fit the ST wheel. The G1500L axle, spider, and splines are the same as a ST1100.

GL1500 Rear Wheel

You want to be sure to get a later model wheel. The early ones had 4 drive fingers on the spider, the ST1100 requires 5 fingers.

If you check with a place that does trike conversions they will likely have some. Or look on flea-bay. You will see prices all over the place but I got mine for a reasonable price. $49 plus $20 shipping.

NOTE: If you purchase a used GL1500 Rear Wheel, make sure to check the bearings or replace them since mileage would be unknown.

~~~

This is a list of the work needed and the prices that I charge:

Brake Hanger.

Rider will provide the stock or E-bay hanger and the boss the forward pin goes through. All years appear to be the same. I need to mill some off the hanger to allow it to move left. I need to remove the steel bushing. I need to make new bushings to allow the move to the left and to go back to stock if a CT isn't for you after trying one. Finally, the boss that the forward pin goes through to keep the hanger in position, needs to be milled. I take off 0.250" to allow the shift to the left.

$130.00

NOTE: The part number for the hanger is 43110-MAJ-G01 and is approximately $136.00 ( New )

Spacers to move left.

I will make spacers for the Spider to keep the splines fully engaged, the Spacer Tube in the drive, and one to replace the one that goes in between the bearing and Hanger, given that the wheel is a different width than the 1100 wheel. $90.00

Contact info for Mark Kunath: twolmaker1 "at" gmail "dot" com

~~~

Comments by KotAOW:

How to determine the correct Rear Wheel from GL1500:

This is the Rear Drive Flange as used on a 1995-2002 ST1100: ( 42630-MT8-305 )

Using a cross-reference fiche as a guide, it can be determined that the same drive flange is also used on a Honda, GL1500, 1988-2003. One can then accurately assume the GL1500 Rear Wheel ( 1988-2003 ) will fit the ST1100 Drive Flange ( 1995-2002 ).

~~~

ST1100 Car Tire Choices

There are not that many choices for the 1100 as we need to stay with a narrower tire than the 1300 can use, because of the swing arm clearance. 175/60/16 is as big as has been used at this time to my knowledge.

~~~

Brands of Car Tires and the PSI that have been documented: http://www.st-owners.com/forums/showthread.php?103999-Brands-of-C-T-and-the-PSI-that-you-run

NOTE: This information gathered March, 2012.

~~~

Sources ( 3/2012 ):

Bridgstone Turanza EL400 175X60X16 - $106.00

Federal Formoza FD2 175X60X16 - $94.80

~~~

Thank You again for your contribution Mark Kunath, aka Bigmak96, STOC #7910

~~~

Following comments by KotAOW:

Disclaimer:

The information contained in this article is for general information only. Whilst the author(s) endeavors to ensure the accuracy of this general information, no statement, representation, warranty or guarantee, express or implied, is given as to its accuracy or appropriateness for use in any particular circumstances.

The author(s) are NOT responsible for any loss or damage whatsoever arising out of or in connection with any information on this specific subject. Users are responsible for making their own assessment of all information contained in this article and are advised to verify such information.

~~~

Purpose:

This article is a collection of many threads posted on different motorcycle forums. It is NOT to be considered a "how-to or step-by-step" procedure for converting your ST1100 w\o ABS to use a Car Tire on the rear.

Also, this article shouldn't be construed as a place to debate the use of a Car Tire on a motorcycle. That subject has been thoroughly scrutinized enough elsewhere by many believers and non-believers.

Each rider must determine the advantages and dis-advantages before continuing down this path to the "Darkside."

~~~

Converting Rear Wheel and Mounting a Car Tire ( ST1100 )

Comments by Mark Kunath:

In order to use a Car Tire or CT on a ST1100 you need to convert to the Honda GL1500 wheel as there is no CT to fit the ST wheel. The G1500L axle, spider, and splines are the same as a ST1100.

GL1500 Rear Wheel

You want to be sure to get a later model wheel. The early ones had 4 drive fingers on the spider, the ST1100 requires 5 fingers.

If you check with a place that does trike conversions they will likely have some. Or look on flea-bay. You will see prices all over the place but I got mine for a reasonable price. $49 plus $20 shipping.

NOTE: If you purchase a used GL1500 Rear Wheel, make sure to check the bearings or replace them since mileage would be unknown.

~~~

This is a list of the work needed and the prices that I charge:

Brake Hanger.

Rider will provide the stock or E-bay hanger and the boss the forward pin goes through. All years appear to be the same. I need to mill some off the hanger to allow it to move left. I need to remove the steel bushing. I need to make new bushings to allow the move to the left and to go back to stock if a CT isn't for you after trying one. Finally, the boss that the forward pin goes through to keep the hanger in position, needs to be milled. I take off 0.250" to allow the shift to the left.

$130.00

NOTE: The part number for the hanger is 43110-MAJ-G01 and is approximately $136.00 ( New )

Spacers to move left.

I will make spacers for the Spider to keep the splines fully engaged, the Spacer Tube in the drive, and one to replace the one that goes in between the bearing and Hanger, given that the wheel is a different width than the 1100 wheel. $90.00

Contact info for Mark Kunath: twolmaker1 "at" gmail "dot" com

~~~

Comments by KotAOW:

How to determine the correct Rear Wheel from GL1500:

This is the Rear Drive Flange as used on a 1995-2002 ST1100: ( 42630-MT8-305 )

Using a cross-reference fiche as a guide, it can be determined that the same drive flange is also used on a Honda, GL1500, 1988-2003. One can then accurately assume the GL1500 Rear Wheel ( 1988-2003 ) will fit the ST1100 Drive Flange ( 1995-2002 ).

~~~

ST1100 Car Tire Choices

There are not that many choices for the 1100 as we need to stay with a narrower tire than the 1300 can use, because of the swing arm clearance. 175/60/16 is as big as has been used at this time to my knowledge.

~~~

Brands of Car Tires and the PSI that have been documented: http://www.st-owners.com/forums/showthread.php?103999-Brands-of-C-T-and-the-PSI-that-you-run

NOTE: This information gathered March, 2012.

| Source | Location | Brand \ Size | PSI | Mileage | Comments |

| Trekker Dave | Rear | Formoza 175X60X16 | 40 PSI | 6,000 | Cranked up the pre-load & damping on my Progressive Suspension rear shock. |

| Front | Bridgestone 023 | 42 PSI | |||

| The Dan | Rear | Formoza 175X60X16 | 40 PSI | 6,900 | It lowered the bike the same as a PR2 |

| Front | |||||

| Bigmak96 | Rear | Bridgstone Turanza 175X60X16 | 38 PSI | 7,500 | I am happy so far. |

| Front |

~~~

Sources ( 3/2012 ):

Bridgstone Turanza EL400 175X60X16 - $106.00

Federal Formoza FD2 175X60X16 - $94.80

~~~

Thank You again for your contribution Mark Kunath, aka Bigmak96, STOC #7910

#79

ST1100 Archive of Wisdom / (Stickie) Derek, STOC #001, th...

Last post by KoTAOW - March 03, 2012, 08:38:35 PMSubmitted by George Catt, STOC #004

~~~

George, in one way, I hate to ask, but you and I are about the same age and I have a son that rides an ST. For what I can learn from it,

would you mind relating the circumstances of Derek's accident?

I can only imagine the pain you have felt...

Ed Lee, STOC #5066,

Lancaster, SC

~~~

Ed, glad to. Need to educate the young'uns. I'm gonna share this with the liST and with ST-Owners and my Chicago friends as there's plenty of newer riders out there who haven't heard the whole story _and_ who might learn from the mistakes of others.

I also have a son (Adam) who rides an ST. He'll read this here, too. If he's the only one, I'll be happy. I know many of you have heard this before. Can't hurt to refresh, tho. We all need to pay more attention, ride like we're invisible, and keep our collective heads up.

---------------

May 27, 1994

Derek was south bound on a local 2-lane near Seneca, S.C. He had just left an HSTA dinner at the next town north. He passed all the others as they left the restaurant, in a hurry to hook up with another buddy who had arrived late.

Sun was setting, not quite dark. Don't know if that was a factor. Car pulled out of a side street from his right, also headed south. Looks like he pulled out to pass her as she made an immediate left into the unmarked left hand T intersection. He was beside her, hit her front left quarter and wheel, put him over an embankment and down into a gully about 30 feet. He landed on his back, his head hit a concrete culvert hard. Ruptured spleen and other internal injuries. First person on the scene was a surgical nurse and EMT was there quickly. No chance.

Driver was cited for failure to yield, said she never saw him. It was dark enuff that his lights should'a showed up easily. Guess it didn't happen. S.C. HP said Derek did nothing wrong but he was probably over the speed limit. When she pulled out, he went left to go around her and she turned left into him. Derek was in the wrong in that he was over the double yellow, but the cop says she pulled out, probably without a full stop and forced him to go left, then turned left into him. There were was a sign showing the T intersection from the right but none showing the T intersection from the left. There is now (after the second fatality less than a year later.)

He may have just thought he could pass with no problem, or she may really have forced him into the left lane when she pulled out. Either way, the crash occurred. He actually went over the side from the edge of the side road, around the east end of the ARMCO barrier that lines the main road. The bike stayed on the ground all the way down, as shown by the tracks. Don't know if he was still on it at that point. The bike bounced so hard at the bottom that it end-oed, going upside down, back wheel first between two trees. We found his radio, previously stored in the tail piece, hanging about 6 feet up in the limbs. Plastic explosion sent shards in all directions.

So, what can yur son (and many others) learn from this. Basically, one thing: SLOW DOWN!! Derek had an admitted "Need For Speed." He was prolly well over the posted 55, on an unknown road, in a basically residential area. He didn't anticipate a problem, still suffering from the delusion of youth: invincibility. The driver was suffering from familiarity, myopia, and the typical BDI syndrome we all know so well. She was probably concentrating on her shopping list, looking south to see that no traffic was gonna slow her progress on to the east bound side street, and didn't even glance left as she pulled out of her side street. Whatever, the combination of youthful exuberance and middle-age myopia resulted in this tragedy.

My thought on the whole thing is that both contributed to the final result. The state was also at fault for not adequately marking the intersection. The driver was in her element and expected nothing unusual. Derek was in his element and _should have_ expected the unexpected. That's the big lesson to be learned.

Here's the bottom line: education comes in four levels:

1. Awareness - ya know something exists (in this case, danger.)

2. Knowledge - ya know about the intricacies of that something (danger can kill ya!)

3. Transfer - ya know _why_ this knowledge is important to ya. Yu'll never get good at anything unless you can make that transfer.

Knowledge is never enuff cause it doesn't raise any passion. Transfer is where the figurative light bulb comes on.

4. Practice, practice, practice - this is where ya take yur knowledge and use it to get good, better, best.

Important to note, too, that learning never stops. Transfer and practice leads to more awareness and more knowledge. Never ending loop. Wisdom comes with experience. Unfortunately, experience usually comes from lack of wisdom. Use the mistakes of others to learn instead'a graduating from the school of hard knocks.

I've read, many years ago, that motorcyclists with over 100,000 miles experience are among the best and safest drivers on the roads. They have proved their "survivability." Usually, that experience comes over several years. In Derek's case, he had just made 100,000 miles, but in only 3 years. Worst thing, to me, about his experience is his previous serious accident, he didn't "learn" his lesson. He was rear-ended about 2 years earlier, totaled his bike, threw him about 30 feet into the ditch. He walked away without a scratch. His "invincibility" shield actually got a boost from that one. So, tho he had the necessary awareness and knowledge, he had not made that absolutely necessary transfer to WHY is it important.

All youse guys and gals reading this, please take his mistake and use it to make that all important leap: ya can't see where yur going with yur head up yur butt.

Here's a set of pics. Take a close notice of the wrecked bike. Imagine what that kind of force can do to the human body. ATGATT (all the gear, all the time) can only help so much.

http://rides.webshots.com/album/109751403eIngqT

Have yur young and new riders read this and look at the pics. Make'em take the MSF basic and Advanced Rider courses. Get'em to do a track day and maybe a Keith Code School. Ride with'em and tell'em what __you_ think they're doing wrong. And ask them their opinion, too, about all kinds of stuff. Ya might learn sumpin'.

George - STOC #004

in Kingman, Arizona

~~~

Thank You again for your contribution George Catt, STOC #004

~~~

Derek, STOC #001, the long story by George Catt

George, in one way, I hate to ask, but you and I are about the same age and I have a son that rides an ST. For what I can learn from it,

would you mind relating the circumstances of Derek's accident?

I can only imagine the pain you have felt...

Ed Lee, STOC #5066,

Lancaster, SC

~~~

Ed, glad to. Need to educate the young'uns. I'm gonna share this with the liST and with ST-Owners and my Chicago friends as there's plenty of newer riders out there who haven't heard the whole story _and_ who might learn from the mistakes of others.

I also have a son (Adam) who rides an ST. He'll read this here, too. If he's the only one, I'll be happy. I know many of you have heard this before. Can't hurt to refresh, tho. We all need to pay more attention, ride like we're invisible, and keep our collective heads up.

---------------

May 27, 1994

Derek was south bound on a local 2-lane near Seneca, S.C. He had just left an HSTA dinner at the next town north. He passed all the others as they left the restaurant, in a hurry to hook up with another buddy who had arrived late.

Sun was setting, not quite dark. Don't know if that was a factor. Car pulled out of a side street from his right, also headed south. Looks like he pulled out to pass her as she made an immediate left into the unmarked left hand T intersection. He was beside her, hit her front left quarter and wheel, put him over an embankment and down into a gully about 30 feet. He landed on his back, his head hit a concrete culvert hard. Ruptured spleen and other internal injuries. First person on the scene was a surgical nurse and EMT was there quickly. No chance.

Driver was cited for failure to yield, said she never saw him. It was dark enuff that his lights should'a showed up easily. Guess it didn't happen. S.C. HP said Derek did nothing wrong but he was probably over the speed limit. When she pulled out, he went left to go around her and she turned left into him. Derek was in the wrong in that he was over the double yellow, but the cop says she pulled out, probably without a full stop and forced him to go left, then turned left into him. There were was a sign showing the T intersection from the right but none showing the T intersection from the left. There is now (after the second fatality less than a year later.)

He may have just thought he could pass with no problem, or she may really have forced him into the left lane when she pulled out. Either way, the crash occurred. He actually went over the side from the edge of the side road, around the east end of the ARMCO barrier that lines the main road. The bike stayed on the ground all the way down, as shown by the tracks. Don't know if he was still on it at that point. The bike bounced so hard at the bottom that it end-oed, going upside down, back wheel first between two trees. We found his radio, previously stored in the tail piece, hanging about 6 feet up in the limbs. Plastic explosion sent shards in all directions.

So, what can yur son (and many others) learn from this. Basically, one thing: SLOW DOWN!! Derek had an admitted "Need For Speed." He was prolly well over the posted 55, on an unknown road, in a basically residential area. He didn't anticipate a problem, still suffering from the delusion of youth: invincibility. The driver was suffering from familiarity, myopia, and the typical BDI syndrome we all know so well. She was probably concentrating on her shopping list, looking south to see that no traffic was gonna slow her progress on to the east bound side street, and didn't even glance left as she pulled out of her side street. Whatever, the combination of youthful exuberance and middle-age myopia resulted in this tragedy.

My thought on the whole thing is that both contributed to the final result. The state was also at fault for not adequately marking the intersection. The driver was in her element and expected nothing unusual. Derek was in his element and _should have_ expected the unexpected. That's the big lesson to be learned.

Here's the bottom line: education comes in four levels:

1. Awareness - ya know something exists (in this case, danger.)

2. Knowledge - ya know about the intricacies of that something (danger can kill ya!)

3. Transfer - ya know _why_ this knowledge is important to ya. Yu'll never get good at anything unless you can make that transfer.

Knowledge is never enuff cause it doesn't raise any passion. Transfer is where the figurative light bulb comes on.

4. Practice, practice, practice - this is where ya take yur knowledge and use it to get good, better, best.

Important to note, too, that learning never stops. Transfer and practice leads to more awareness and more knowledge. Never ending loop. Wisdom comes with experience. Unfortunately, experience usually comes from lack of wisdom. Use the mistakes of others to learn instead'a graduating from the school of hard knocks.

I've read, many years ago, that motorcyclists with over 100,000 miles experience are among the best and safest drivers on the roads. They have proved their "survivability." Usually, that experience comes over several years. In Derek's case, he had just made 100,000 miles, but in only 3 years. Worst thing, to me, about his experience is his previous serious accident, he didn't "learn" his lesson. He was rear-ended about 2 years earlier, totaled his bike, threw him about 30 feet into the ditch. He walked away without a scratch. His "invincibility" shield actually got a boost from that one. So, tho he had the necessary awareness and knowledge, he had not made that absolutely necessary transfer to WHY is it important.

All youse guys and gals reading this, please take his mistake and use it to make that all important leap: ya can't see where yur going with yur head up yur butt.

Here's a set of pics. Take a close notice of the wrecked bike. Imagine what that kind of force can do to the human body. ATGATT (all the gear, all the time) can only help so much.

http://rides.webshots.com/album/109751403eIngqT

Have yur young and new riders read this and look at the pics. Make'em take the MSF basic and Advanced Rider courses. Get'em to do a track day and maybe a Keith Code School. Ride with'em and tell'em what __you_ think they're doing wrong. And ask them their opinion, too, about all kinds of stuff. Ya might learn sumpin'.

George - STOC #004

in Kingman, Arizona

~~~

Thank You again for your contribution George Catt, STOC #004

#80

ST1100 Archive of Wisdom / (Stickie) The ST Owners Club (...

Last post by KoTAOW - March 03, 2012, 08:21:36 PMSubmitted by Adam Koczarski, STOC #265

Original article can be found here: http://koczarski.com/Motorcycles/STOChistory/STock%20STartup.pdf

~~~

Late in 1993 when Derek Catt and Charlie Woods dreamed up the idea of having an Electronic ST Owners Club, we were attempting to work around the then leading edge of electronic communications, UNIX servers and PINE/ELM mail programs. There were no WEB browsers like Netscape or Mosaic, there were no email programs like Free Agent or WinVN.

Our mail list was just that, a simple email with everyones email address appended to the recipient header. Derek mailed out the STUFF newsletter electronically. Most of the newsletters were excerpts from the months collection of emails Derek received concerning products members of the list had bought or tried that were used or related to the ST1100.

At that time, most of the people on the email list were DoD members (Dennizens of Doom). The DoD is mostly related to the Usenet news group REC.MOTORCYCLES. And so, in true DoD fashion, the STOC was formed, although there is no connection between the DoD and the STOC, or the ST Newsletter published in Houston, Texas.

The application for a STOC number was a simple, funny idea to poke fun at the sport bike side of the ST yet, providing our members their own way of recognizing others that had the same interest in ST1100's by including their STOC number at the bottom of each email they sent.

After Derek's untimely death, Jim Alexander took over the task of compiling the monthly STUFF newsletters and continued until his transfer to another job outside the USA. Derek's father, George Catt then took up the task of publishing the STUFF. All the while, the STOC list of members was growing.

The most significant improvement for the STOC members was the creation of the WEB page by Michael Galassi. The Internet had finally come of age and it was becoming easier for people to retrieve information. Michael did an excellent job of collecting everything that had transpired in the past and designed and maintains the WEB page for us.

Another significant improvement for the STOC members was the creation of a "list processor" where any one member could email his/her questions or comments to the entire list of people on the list with only a single message. We thank Mike Morrison for this improvement.

If you search the Internet using Yahoo for motorcycles, you'll find the STOC WEB page listed... We're famous.

The December 1995 Motorcycle Consumer News (MCN) reader survey (page 36) form lists the STOC as one of the choices for current motorcycle organizations of which you may be a member.

I can think of no greater tribute to those who have been involved in the making of the STOC than to see the "organization" recognized in a national motorcycle publication.

I know Derek Catt is smiling down at us for our accomplishment.

See'ya

Charlie Woods #002

~~~

STOC cofounder, Derek Catt, #001 and his 97 year old Great Grandmother, circa 1992.

~~~

More STOC history, newsletters and pictures can be found at this link: http://koczarski.com/Motorcycles/STOChistory/STOChistory.htm

~~~

Thank You again for your contribution Adam Koczarski, STOC #265

Original article can be found here: http://koczarski.com/Motorcycles/STOChistory/STock%20STartup.pdf

~~~

The ST Owners Club (STOC) has come of age by Charlie Woods ( 1993 )

Late in 1993 when Derek Catt and Charlie Woods dreamed up the idea of having an Electronic ST Owners Club, we were attempting to work around the then leading edge of electronic communications, UNIX servers and PINE/ELM mail programs. There were no WEB browsers like Netscape or Mosaic, there were no email programs like Free Agent or WinVN.

Our mail list was just that, a simple email with everyones email address appended to the recipient header. Derek mailed out the STUFF newsletter electronically. Most of the newsletters were excerpts from the months collection of emails Derek received concerning products members of the list had bought or tried that were used or related to the ST1100.